Wear-Resistant Steel (NM Series)

1. Application and Features

1. Application and Features

The NM series quenched and tempered steel produced in LY Steel is thin in gauge, good in shape, with stable property and quality as well as high production efficiency. This series of product is applied to medium and heavy truck, dump truck, garbage collection truck, concrete mixer, industrial fan, hopper and crushed aggregates etc. The property, quality and delivery technical specification of wear-resistant steel in LY Steel has reached the level of similar import products.

The thickness and the dead-weight of product can be greatly reduced if wear-resistant steel of LY Steel is used instead of common structural steel, which is energy saving and environment friendly. Comparing with the original dumper, the actual dead-weight of U-shape dumper processed with NM400 is reduced from 12 tons to 6 tons. The application of NM300 rather than 520JJ can significantly improve the corrosion resistance of the barrel and rotary vane in the concrete mixer, with corrosion resistance reaching to two times of 520JJ, which can greatly improve the lifetime of the concrete mixer. The hardness of NM450 can reach to more than 3 times than structural steel Q345, the wear resistance can be improved by 2 to 3 times than Q345, thus the lifetime of the sheet can be elongated greatly.

2. Delivery Standard

| Steel Grade |

China Standard |

Similar Product of Other Suppliers |

| JFE |

SSAB |

| NM300 |

GB/T 24186-2009 |

EH300 |

HARDOX300 |

| NM360 |

GB/T 24186-2009 |

EH360 |

HARDOX360 |

| NM400 |

GB/T 24186-2009 |

EH400 |

HARDOX400 |

| NM450 |

GB/T 24186-2009 |

EH450 |

HARDOX450 |

| NM500 |

GB/T 24186-2009 |

EH500 |

HARDOX500 |

3. Available Sizes

| Steel Grade |

Supply Thickness (mm) |

Supply Width (mm) |

Supply Length (mm) |

| NM300 |

4-25 |

900-2000 |

2000-12000 |

| NM360 |

4-25 |

900-2000 |

2000-12000 |

| NM400 |

4-25 |

900-2000 |

2000-12000 |

| NM450 |

4-25 |

900-2000 |

2000-12000 |

| NM500 |

4-25 |

900-2000 |

2000-12000 |

The NM series high strength wear-resistant steel produced by LY Steel is delivered as sheet in accordance with China standard GB/T24186-2009.

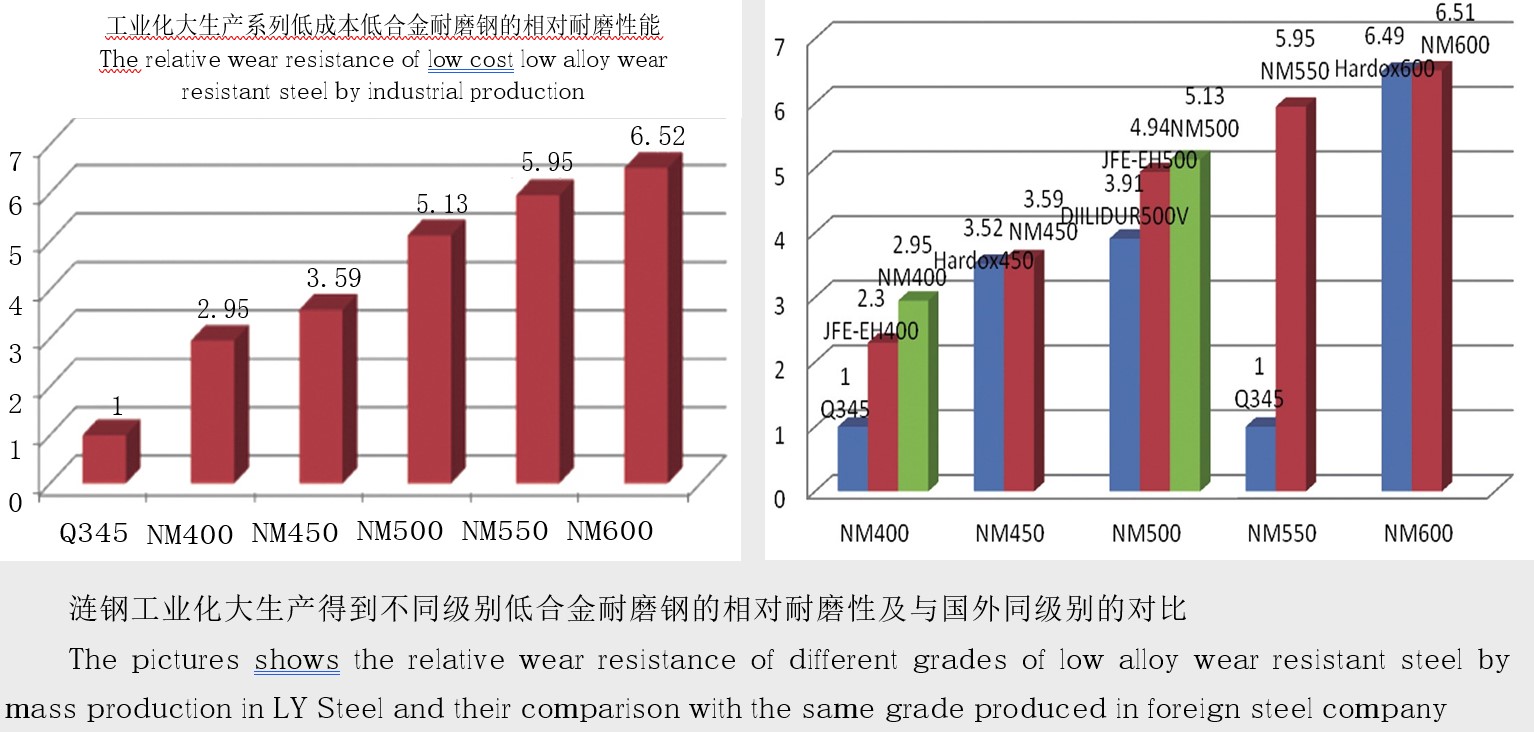

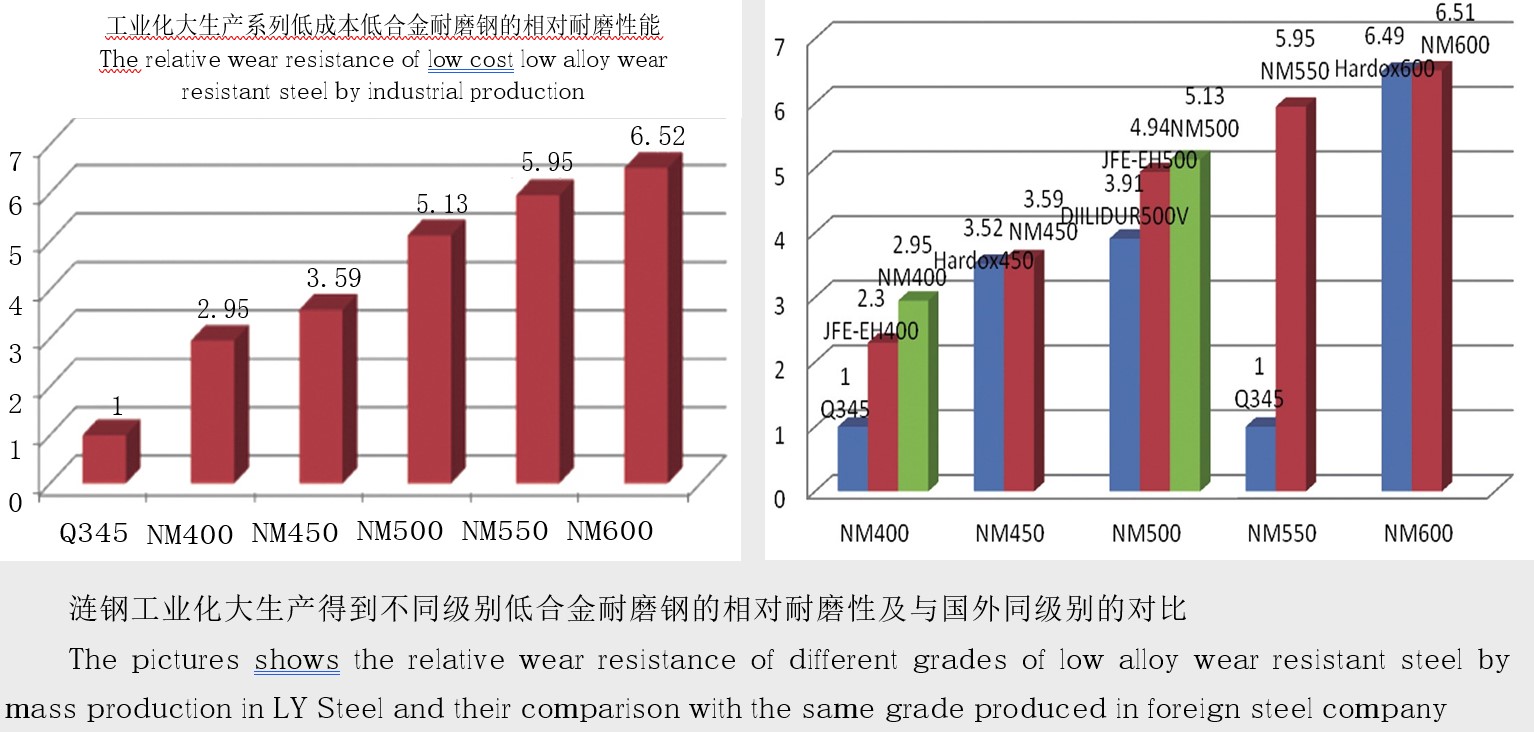

3. Wear-Resistance Property

The wear-resistance steel produced by LY Steel possess excellent wear-resistance properties, the comparison data of wear-resistance property between LY Steel and foreign well-known manufacturers is showed as below:

1) Slide Wear Test Data: NM400 vs. HARDOX400

| Wearing Period |

Average Thickness Loss µm

HARDOX400

|

Average Thickness Loss µm

NM400 |

Relative Wearability NM400/HARDOX400

|

| 0-3 min |

3.950 |

3.696 |

1.069 |

| 3-6 min |

3.869 |

3.603 |

1.074 |

| 6-9 min |

3.666 |

3.556 |

1.031 |

2) Sliding Wear Test Data: NM450 vs. HARDOX450

Table1: Abrasive Wear Test – Result with Impact

Grade |

Impact Energy/J |

Quality Before Wear /g |

Quality After Wear /g |

Wear Loss/g |

Relative Wearability

NM450/HARDOX450

|

| LGNM450 |

2 |

14.80762 |

14.7071 |

0.10052 |

1.0625 |

| HARDOX450 |

15.00051 |

14.89371 |

0.10680 |

1 |

| LGNM450 |

4 |

15.67336 |

15.50789 |

0.16547 |

1.03197 |

| HARDOX450 |

14.36629 |

14.19553 |

0.17076 |

1 |

Table2: Abrasive Wear Test: Result without Impact (NM450 vs. HARDOX450)

Grade |

Wear Time/h |

Quality Before Wear/g |

Quality After Wear /g |

Wear Loss/g |

Relative Wearability

NM450/HARDOX450 |

| LGNM450 |

36 |

16.62430 |

16.60013 |

0.02417 |

1.093 |

| HARDOX450 |

15.74163 |

15.71521 |

0.02642 |

1 |

3) NM500 vs. SB50

Table 3: Sliding Wear Test Result between NM500 and SB50

| Wearing Time |

Average Wear Rate /%

SB50

|

Average Wear Rate/%

NM500 |

Relative Wearability NM500/SB50 |

| 20 min |

0.23% |

0.21% |

1.095 |

| 40 min |

0.47% |

0.40% |

1.175 |

| 60 min |

0.71% |

0.61% |

1.164 |

Key Applications:

The wear-resistant steel plate of Lianyuan Steel can be used to make first-class equipment and spare parts, which can withstand the long-term industrial and mining challenges, maximize the service life, reduce the risk of failure and improve the productivity. It is mainly used in equipment wear-resistant parts, dump truck carriage, concrete mixer, underground mine, cement industry, road building industry, mining stone, open pit and metallurgical industry.

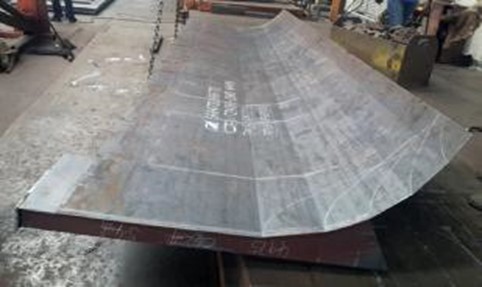

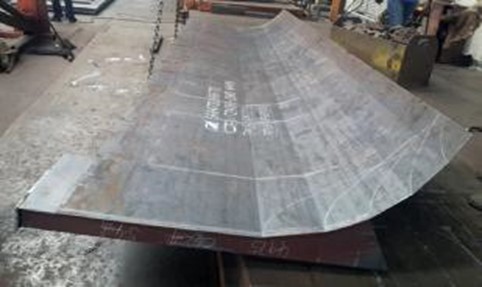

1. Dump Truck

In terms of economy or energy conservation and environmental protection, wear-resistant dump truck is an inevitable trend in the future. The wear-resistant steel of Lianyuan Steel is widely used in the production enterprises of dump trucks.

2. Concrete Mixer

2. Concrete Mixer

At present, the main material used for concrete mixer is 520JJ, but because the wear resistance of 520JJ can not meet the needs of customers, many concrete mixers hope to launch materials with better wear resistance than 520JJ. NM300 for concrete mixer has economic advantages: less materials, lighter weight and higher wear resistance.

3. Mining and Open Pit

3. Mining and Open Pit

Mining and open-pit operation have high requirements for equipment. In terms of equipment wear resistance, if the material is not selected properly, it will pay a high price. The application of wear-resistant steel plate in this field has significant advantages. The carriage and blade plate wear-resistant components of forklift, bulldozer, mining dump truck and excavator can be made of Lianyuan Steel wear-resistant steel plates NM400, NM450 and NM500. Wear resistant components of quarry and open pit equipment such as crusher, feeder, loader, screen and loader can be made of wear-resistant steel plate NM450 or NM500 of Lianyuan Steel.

4. Underground Mine

4. Underground Mine

Underground mine operation has high requirements for equipment. In terms of equipment wear resistance, Lianyuan Steel wear-resistant steel plate NM360 / 400 / 450 / 500 product series can be selected. The steel plate is suitable for underground mine equipment such as scraper, buffer bucket, mining truck, excavator, crusher, various hoppers, screening machine, chute (coal scraper).

5. Cement Industry

5. Cement Industry

The wear-resistant steel plate of Lianyuan Steel is widely used in mining, transportation and processing of cement industry. It can be widely used in the side plate and bottom plate of dump truck carriage, knife plate of excavator and loader, upper feed hopper and feed plate of crusher, side plate of conveyor, hopper of elevator and raw material processing workshop, such as discharge chute, grid plate, rotor sealing ring and deflection plate of separator Grinding components. For wear-resistant steel members in different application places, different series of wear-resistant steel plates (such as NM400 / NM450 / NM500 / NM600, etc.) can be selected.

6. Road Construction Industry

6. Road Construction Industry

It can be widely used in the mining, transportation and processing of road construction industry, such as hydraulic hammer, side plate and bottom plate of dump truck carriage, knife plate of excavator, bulldozer and loader, lining plate of crusher, chute, shovel plate of road leveler and iron plate of asphalt paver. Different series of wear-resistant steel plates (such as NM400 / NM450 / NM500 / NM600, etc.) can be selected for wear-resistant steel members in different application places

7. Metallurgical Industry

7. Metallurgical Industry

It can be widely used in the production of iron and gas in the metallurgical industry, such as rotary trough, fixed trough, liner, waste hopper for blast furnace purification, screen for ore, shock-absorber for conversion, transfer trough, discharge hopper, bottom pad feeder, discharge trough, transfer equipment for coke, transfer trough, stacking trough, liner for mixer, container for combined chute of transfer belt in sintering plant The lining plate of feeder, raw material roller feeder and other wear-resistant components. For wear-resistant steel members in different application places, different series of wear-resistant steel plates (such as NM400 / NM450 / NM500 / NM600, etc.) can be selected.

Product Advantages of Performance

1) Reduce their own weight: the steel plate is based on the addition of a number of alloy elements needed to design a series of low-alloy high-strength wear-resistant steel plate, through the steel plate processing, so that it can have a variety of specifications of high hardness (wear resistance). As a result, the weight of structural parts can be significantly reduced.

2) Excellent welding performance: specially considering the welding performance of steel plate, on the premise of ensuring the wear resistance and mechanical properties of steel plate, reduce the carbon equivalent of steel plate as much as possible, and carry out unique composition design. And through the corresponding process test, select the best matching welding materials, which can be used in both steel plate and welding materials.

3) Good toughness: by strictly controlling the chemical composition, minimizing the content of harmful elements in steel, and selecting reasonable heat treatment conditions, the steel plate has good toughness. Therefore, a highly reliable structure can be constructed for the brittle failure of wear-resistant components.

4) Good processing performance: due to the uniform control of steel plate performance, excellent performance matching, and good toughness, steel plate bending, drilling, cutting and other mechanical processing performance are excellent.

5) Thin thickness and good flatness: it can produce 3-25.4mm thick, 900-2050mm wide and the maximum length 16,000mm steel plate. It can provide the thinnest wear-resistant steel plate with excellent flatness in China.

Quality Control Level of Steel Plate

1) The purity of molten steel is high and the impurity content is very low, which can reach [P] < 0.010%, [S] < 0.005%, [n] < 50ppm, [H] < 2ppm, [O] < 15ppm;

2) The range of composition fluctuation between different heats with the same specification of steel plate is small.

3)The hardness of steel plate is controlled evenly, and the difference between the hardness of steel plate and that of steel plate is small.

4)The tolerance of steel plate shall be strictly controlled, the shape of the plate shall be flat, the surface shall be smooth, and the unevenness can be controlled below 5 mm/m.